Nagykanizsa

Manpower

people

Number of machines

machines

Product portfolio

types

qualified suppliers

suppliers

shopfloor area

office area

The Nagykanizsa factory became a member of the Technocar group in 2006, when Technocar purchased some minority interests in a machining company in Nagykanizsa.

Tecnocar acquired full control in 2015, since then the factory has been continuously growing both in its output and productivities.

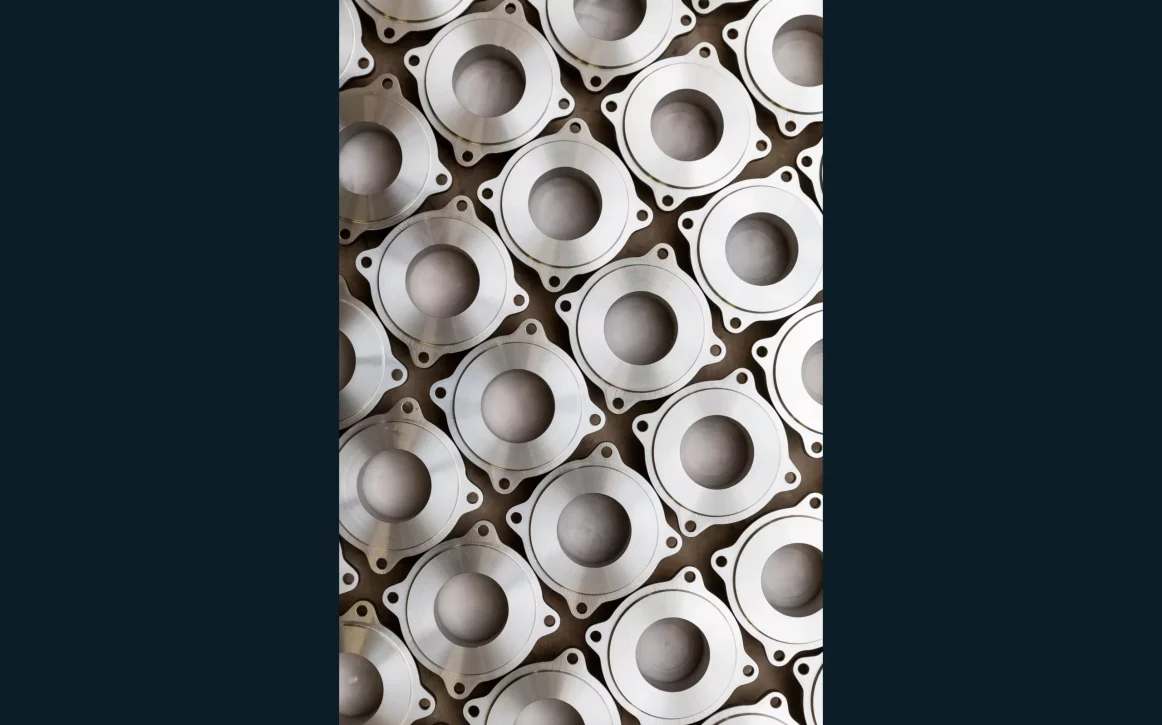

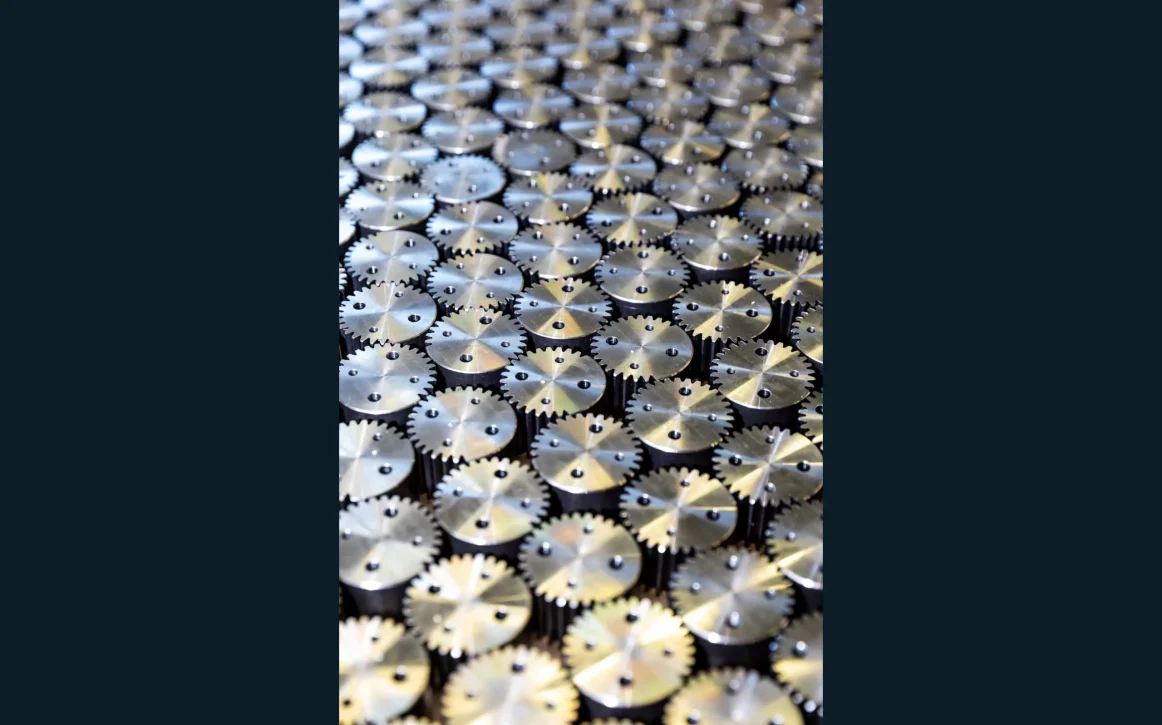

Nagykanizsa site’s functioning, – contrary to the other two locations -, is a single line operation, their activity is CNC machining. In its capacity, Nagykanizsa is the biggest supplier of machined parts for Technocar’s two other sites, 70% of their production goes to Helvécia’s and Bicske’s factories.

Machining

CNC horizontal, and vertical milling machines, CNC lathes with driven tool holders, Y axis, and counter spindle. Conventional milling machines, and lathes.

Conventional hole, and cylindrical grinding machines.

Welding

MIG / TIG / Laser welding machines with water cooling system for steel, stainless steel and aluminium welding. Rotary tables for large and small parts. Welding robots for high runners. Spot welding capabilities for sheet metal parts.

Painting

Semi automatic painting line with conveyor and

drying chamber, painting chambers for large parts.

Grit blasting

Automatic wheel shotblasting machines, sand and glass bead blasting chambers.

CMM / Scanning

Coordinate measurements and optical scanning of parts to be inspected. Leak testing of critical parts by using special Helium Leak tester

Flame cutting

CNC controlled flame cutting machine is applicable for thick hot rolled sheet metal processing.