Helvécia

MANPOWER

people

Number of machines

machines

Product portfolio

types

qualified suppliers

suppliers

shopfloor area

office area

This site was the first one in our company’s history. Our predecessor company, Technocar kft, was founded in Helvécia in 1991.

The plant was expanded and renovated several times over the years. Today, this factory has become the largest and most complex site of Technocar, out of the three locations, what we presently have.

Currently, six different departments operate here in a total shopfloor area of nearly 4,000 m2.

In this facility we can offer many different services; like CNC and conventional machining, MIG/TIG/Laser welding for material of carbon and stainless steel and aluminium, flame cutting, sheet metal roll- and tube bending, pressing & stamping, grit & sand blasting, and wet paintings.

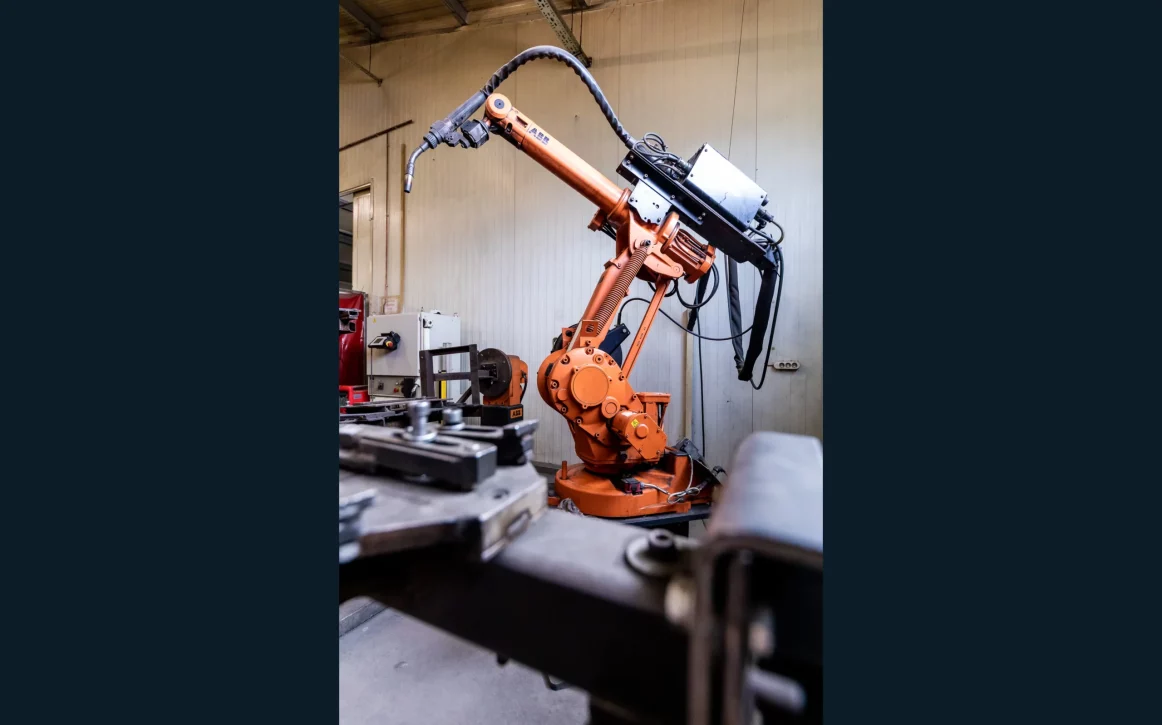

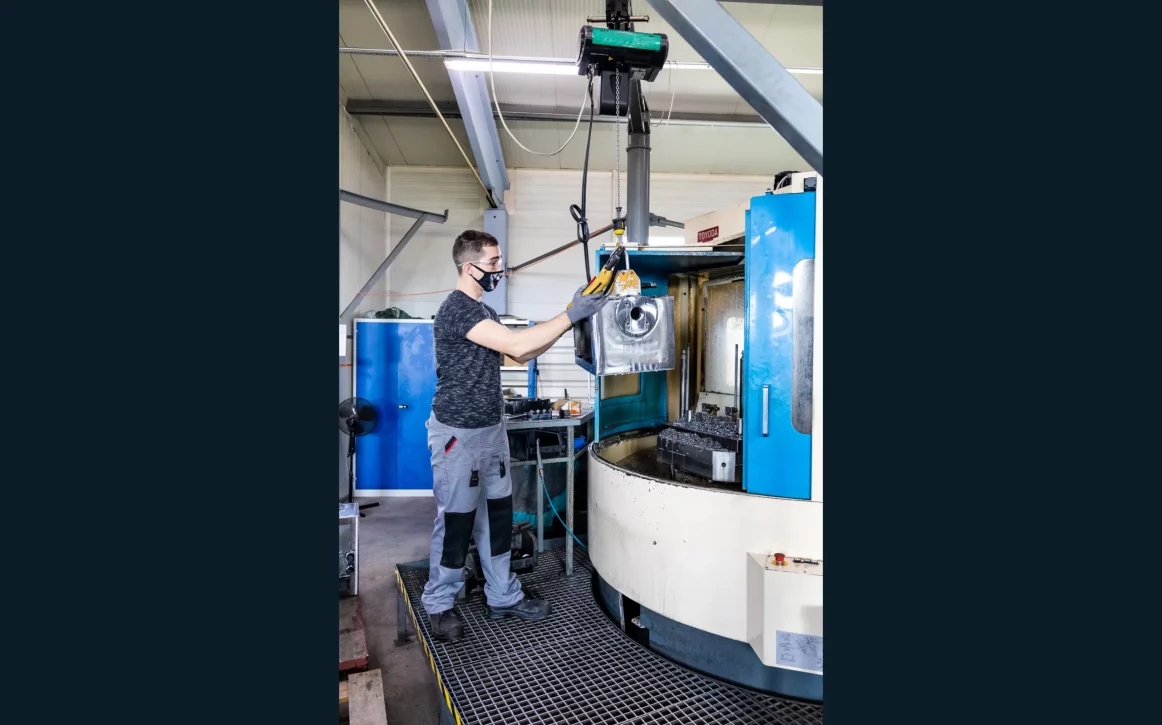

This site is well equipped with the most sophisticated CNC and robotic machineries & technologies. Complex, sheet metal fabricated structures can be manufactured here with the help of most modern technologies.

Machining

CNC horizontal, and vertical milling machines, CNC lathes with driven tool holders, Y axis, and counter spindle. Conventional milling machines, and lathes.

Conventional hole, and cylindrical grinding machines.

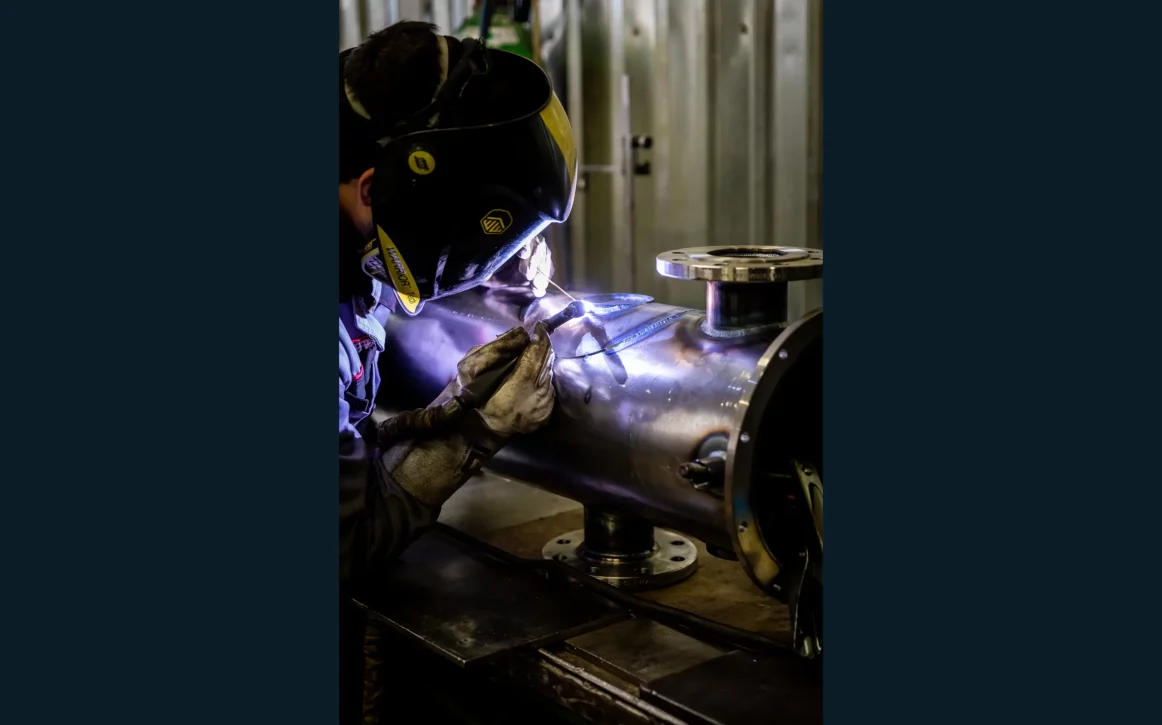

Welding

MIG / TIG / Laser welding machines with water cooling system for steel, stainless steel and aluminium welding. Rotary tables for large and small parts. Welding robots for high runners. Spot welding capabilities for sheet metal parts.

Painting

Semi automatic painting line with conveyor and

drying chamber, painting chambers for large parts.

Grit blasting

Automatic wheel shotblasting machines, sand and glass bead blasting chambers.

CMM / Scanning

Coordinate measurements and optical scanning of parts to be inspected. Leak testing of critical parts by using special Helium Leak tester

Flame cutting

CNC controlled flame cutting machine is applicable for thick hot rolled sheet metal processing.